-

Posted By Editorial Staff

-

-

Comments 0

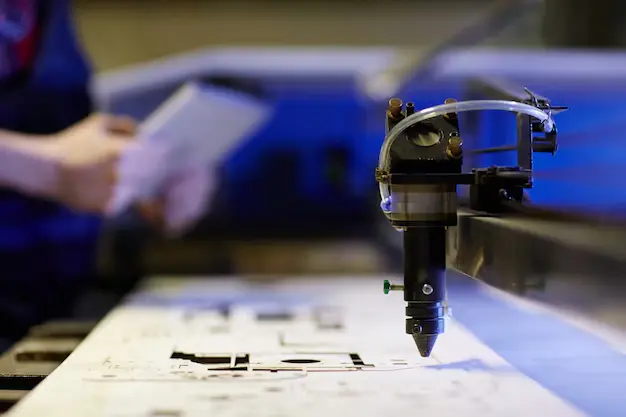

Computer Numerical Control (CNC) machines have become a cornerstone in modern manufacturing, woodworking, metalworking, and hobbyist projects. Whether you’re a seasoned professional or diving into CNC for the first time, selecting the right machine can feel overwhelming.

With so many features, specs, and price points to consider, understanding what really matters can help you make a smart and informed decision—especially when searching for the right cnc machine for sale.

Table of Contents

Toggle1. Define Your Purpose

Before getting into the technical details, it’s important to determine what you plan to do with the CNC machine. Are you working with wood, metals, plastics, or composites? Are you creating large furniture pieces or small, intricate parts?

Your application will influence the type of CNC machine you need, from routers and mills to lathes and plasma cutters. Understanding your goals helps narrow down the machine size, spindle power, and overall capabilities required.

2. Consider Machine Size and Work Area

CNC machines come in a variety of sizes, and choosing the right footprint is key. The size of your workspace and the dimensions of your projects will determine the best fit. Smaller desktop CNCs are great for hobbyists or small part production, while larger machines can handle sheet materials and bulkier jobs. Look at both the machine’s overall dimensions and its cutting area to ensure it aligns with your needs and space limitations.

3. Frame Construction and Rigidity

A CNC machine’s structural design directly affects its performance and accuracy. Machines built with solid, rigid frames (usually made from steel or aluminium) reduce vibrations and improve precision. While lighter machines may cost less and be easier to move, they often compromise on stability and longevity. A well-built frame ensures smoother cuts and higher repeatability over time, especially during heavy or prolonged use.

4. Type of Drive System

The drive system controls how the machine moves along its axes. The most common types include lead screws, ball screws, and rack-and-pinion systems. Ball screws offer high precision and minimal backlash, making them ideal for detailed or complex work.

Rack-and-pinion systems, on the other hand, are better suited for faster and larger cuts. Understanding the pros and cons of each system helps you select one that suits your workload and accuracy requirements.

5. Spindle Power and Speed

The spindle is the part of the CNC machine that holds and spins the cutting tool. Its power and speed determine how efficiently it can cut through different materials.

More powerful spindles can handle denser materials like metal or hardwood, while lighter spindles may be enough for plastics or softwood. Variable speed control is another useful feature, allowing you to tailor the spindle’s RPM to the material and type of cut.

6. Software Compatibility

CNC machines rely on software for design and operation, so it’s essential to check what programs are compatible. Many machines support standard G-code and work with popular CAD/CAM software like Fusion 360, VCarve, and Carbide Create.

Some manufacturers offer proprietary software, which may be user-friendly but less flexible. Look for a machine that gives you room to grow with advanced tools and workflows.

7. Ease of Assembly and Use

Not all CNC machines come fully assembled. If you’re a beginner, look for a machine with a clear, guided assembly process or one that arrives pre-assembled. User-friendly controls, touchscreen interfaces and well-documented manuals can make a big difference, especially if you’re learning the ropes. Machines with intuitive setup and operation tend to get used more consistently and effectively.

8. Support and Community

One often overlooked aspect is the level of support and community around a CNC brand. Reliable customer service, active forums, tutorial videos, and downloadable resources are incredibly helpful when troubleshooting or learning new skills. A strong user community can also offer tips, mods, and project inspiration, which is especially valuable for DIYers and small business owners.

9. Upgrade Options and Expandability

Your CNC needs might evolve over time, so it’s wise to choose a machine that allows for future upgrades. Whether it’s adding a laser attachment, dust collection system, or expanding the work area, modularity can extend the life and versatility of your machine. Machines that support open hardware standards or accessory add-ons offer more flexibility in the long run.

10. Budget and Value for Money

Finally, consider your budget—but think beyond just the price tag. A cheaper machine might come with compromises in build quality, precision, or support. On the other hand, investing a bit more upfront can result in better performance and fewer headaches. Focus on value for money: durable construction, reliable components, and solid support often justify a slightly higher cost.

Conclusion

Buying a CNC machine is an investment in your craft, business, or passion project. Taking the time to understand your needs and comparing machine features ensures you choose a tool that’s both capable and dependable. Whether you’re carving intricate designs or cutting large panels, the right CNC machine can open the door to endless creative and practical possibilities.